Cream Chargers Technological Advancements: Enhancing Culinary Efficiency

FastGas Blog

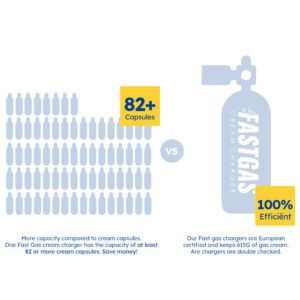

Cream chargers, small canisters filled with nitrous oxide (N2O), have become a staple in modern culinary arts, providing a way to instantly whip cream and enhance the presentation of many dishes and drinks. Integrating advanced technology within these tools has marked a significant leap in functionality and sustainability ensuring cream chargers’ technological advancements. Brands such as FastGas are in charge of implementing these cutting-edge features, such as stainless steel construction for durability and precision engineering to fine-tune gas release, contributing to a more consistent whipped cream quality and efficient gas usage.

Furthermore, as consumer demand for quality and convenience grows, manufacturers respond with innovative designs that streamline the whipping process. Also, the advancements in cream chargers cater to professional chefs, gastronomes, and home cooks seeking restaurant-quality results in their kitchens. From improved materials to smart technology integration, the current trajectory of cream charger development sets new culinary trends while considering the environmental impact by exploring greener gas alternatives.

Key Takeaways

- Cream chargers have evolved with advanced technological features for enhanced performance and sustainability.

- Improved materials and smart integrations signify a notable shift in the functionality of cream chargers.

- Continued innovations in cream charger technology reflect consumer demands for quality, efficiency, and environmental consciousness.

Innovations in Cream Charger Technology

Recent advancements have ushered in a transformative era for cream charger technology, directly impacting the quality of nitrous oxide used and leading to broader applications within the culinary industry. Further, understanding these changes will inform how you utilise cream chargers for various gastronomic tasks, from creating foams to enhancing sauces and mousses.

Advancements in Manufacturing and Materials

The manufacturing of cream chargers has seen significant improvements with the adoption of high-grade steel and recyclable materials. Moreover, this shift enhances the durability and lifespan of whipped cream dispensers and reduces their environmental footprint. Also, you can now find more efficient cream chargers, ensuring the purity and quality of the nitrous oxide gas they contain.

Improving Culinary Techniques and Applications

With innovation in cream charger technology, the culinary world has enhanced its ability to craft textured desserts, beverages, and other culinary creations. Cream chargers, like those developed by FastGas, provide you with greater control, speed, and consistency, which is vital for techniques in molecular gastronomy. In addition, the advancements in the technology allow for a refined texture in foams and a stable shelf life for prepared whipped cream.

Enhancing Safety and Sustainability

Your safety and responsibility towards the environment are central to the new designs of cream chargers. Features have been introduced to ensure proper disposal and responsible use, minimising the risk associated with nitrous oxide. Moreover, sustainable manufacturing processes and designs for recyclability help reduce these tools’ ecological impact.

Developing New Product Features

Cream charger technology now features product-specific innovations, such as smart integration that informs you when the cartridge is empty and precision engineering to fine-tune gas release. These features aim to boost the efficiency of your culinary tasks, allowing for high-quality results with minimal wastage.

The Role of Cream Chargers in Modern Culinary Arts

Cream chargers have become an indispensable tool in modern culinary arts, enabling you to produce a variety of textures and flavours. The latest advancements ensure that cream chargers meet the evolving needs of the culinary sector by allowing you to experiment with new recipes and methods, pushing the boundaries of traditional whipped cream applications.

Consumer Engagement and Market Dynamics

Technological advancements in cream chargers have led to a notable shift in market dynamics and consumer engagement patterns, focusing on convenience, versatility, and sustainability.

Demand and Supply Factors

Demand for cream chargers is influenced by their increasing use in domestic and commercial settings for creating whipped cream, culinary foams, and flavour infusions. Also, supply has responded by integrating smart features into chargers, like FastGas’s latest technology, which ensures rapid aeration without compromising quality. Availability hinges on efficient production and distribution networks to meet the growing needs of consumers.

Evolving Preferences and Practical Uses

Your preferences are evolving towards more convenient culinary tools. Cream chargers now often come with features for more controlled dispensing, enabling mixologists and chefs to innovate with culinary foams and infusions. Also, their versatility is central to modern kitchens, encouraging experimentation and widening the scope of culinary uses.

Environmental Considerations

As awareness of environmental impact grows, the demand for sustainable options in cream chargers has surged. Furthermore, manufacturers are exploring making their products more eco-friendly, from recycling programs to developing chargers that minimise greenhouse gas emissions. Also, they focus on reducing waste, particularly from single-use items.

Educating Users on Best Practices

There is a recognised need to educate you on the safe handling and disposal of cream chargers to mitigate health risks and environmental harm. Furthermore, manufacturers have stepped up their efforts to communicate safety guidelines and proper cleaning techniques, ensuring you can enjoy convenience without issues.

Culinary and Bartending Innovations

Your culinary landscape is ever-changing, and with it, the incorporation of cream chargers in culinary and bartending settings. Also, the ability to swiftly aerate liquids for foams and infusions allows creativity and adds a unique flavour profile to dishes and drinks. Moreover, manufacturers are innovating to keep up with your demands for efficiency and the ability to enable culinary experimentation.

Frequently Asked Questions

Cream charger technology enhancement offers novel culinary capabilities, such as revolutionised whipping efficiency and expanded gastronomic creativity.

What advantages do contemporary cream chargers offer over traditional methods?

Contemporary cream chargers facilitate a more controlled whipping process, enabling you to achieve precise textures and consistency. Also, innovations by brands like FastGas have introduced materials and engineering that enhance durability and performance.

In what additional culinary applications can cream chargers be utilised?

Cream chargers are highly versatile, extending beyond dessert garnishing to food infusion with intense flavours, creation of nitro beverages, and foamy sauces that can bring a gourmet touch to your savoury dishes.

What is the historical timeline for the development of the whipped cream charger?

Originally conceived to provide a rapid and convenient method of whipping cream, cream chargers have evolved since their inception in the mid-20th century, reflecting advancements in gas containment and culinary tools.

How have recent innovations in cream charger design impacted their functionality?

Innovations in design, such as precision-engineered components and smart technology integration by companies like FastGas, have led to cream chargers that offer improved gas efficiency and user experience.

What environmental considerations are being addressed by the latest cream charger technologies?

The latest cream charger technologies are looking into sustainable gas options and materials to lessen the environmental impact, reflecting a commitment to eco-friendliness in culinary tool production.

What safety measures have been integrated into modern cream chargers?

Modern cream chargers now incorporate safety features that ensure proper handling and operation, including pressure regulation mechanisms and robust container materials to prevent gas leakage and user injury.